By Natalie Fortman, summer intern at David Gardiner and Associates, in collaboration with Jennifer Kefer

Last week, two reports—one from the Rhodium Group and the other from DGA’s Alliance for Industrial Efficiency—highlighted the challenges and opportunities for energy use and greenhouse gas emissions in the industrial sector. These reports also raise issues of regulatory and informational barriers to the further implementation of energy efficiency in the industrial sector.

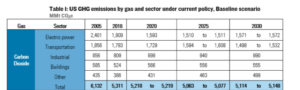

The Rhodium Group released their annual Taking Stock report, which seeks to provide an independent analysis of progress toward U.S. climate commitments. The report analyzes political, economic, and energy trends to predict greenhouse gas emissions from different sectors. While most economic sectors examined in the report are achieving an overall decrease in emissions, the carbon emissions of the industrial sector are notably increasing and are predicted to continue doing so.

U.S. industry is currently the third largest emitter of carbon dioxide in the country and the Rhodium Group report predicts emissions will increase. Emissions from the industrial sector are expected to rise 10% above 2005 levels by 2025 and continue growing through 2030. The report identifies two reasons for this increase – energy intensive manufacturing processes and an abundance of cheap natural gas. The Taking Stock report also indicated the US is not currently on track to meet the 26-28% emissions reduction commitment by 2025 outlined in the Paris Climate Agreement.

U.S. industry is the third largest emitter of carbon dioxide, and emissions are expected to continue increasing through 2030

However, the Taking Stock report included some encouraging findings. U.S. climate policies and regulations were able to reduce greenhouse gas emissions to 12% below the 2005 baseline in 2016 and emissions are expected to dip as low as 20% by 2025. Much of this was achieved in the electric power sector, where emissions are now 25% below 2005 levels. Methane emissions were also significantly reduced, thanks to technological advancements in landfills and coal mines.

The Rhodium Group also notes that several states, cities, and businesses are stepping up to assume climate leadership. Since the withdrawal of the U.S. from the Paris Climate Agreement, 16 states as well as Puerto Rico, 240 American cities, and 1,905 businesses and investors have promised to meet the goals set forth in the historic agreement.

A report from the Alliance for Industrial Efficiency also found that U.S. manufacturers are acting to combat climate change, and they’re saving money at the same time. The Alliance found 79% of the largest manufacturing companies in the country have public greenhouse gas reduction targets and 43% have public energy efficiency targets. Many of these companies cite cost savings and sustainability as the main reasons for their goals. “Cutting energy use is good for our bottom line, and the planet,” says Cargill Sustainability Director Peter Dahm, who was interviewed for the report. Companies achieved or plan to achieve these goals through efficiency enhancing technologies like combined heat and power (CHP). CHP is an onsite energy generator that also produces heat to be used in manufacturing processes and is much more efficient than traditional electric power production.

The Alliance report identified barriers to industrial energy efficiency that may prevent more manufacturers from setting or achieving these goals. Many technological solutions to improve efficiency require a large amount of upfront capital and typically have longer payback periods, making it difficult for companies to invest in them without assistance from government or utility backed incentives. Additionally, certain regulatory provisions allow large users of electricity to be exempt from paying fees for utility energy efficiency programs, known as “opt outs”, leaving fewer resources for companies to achieve their goals.

The Alliance suggests that companies, utilities, and governments must work together to reduce and eliminate these barriers, a point further reinforced by the Rhodium Group’s finding that more needs to be done to reduce emissions in the industrial sector. Companies should document and share how they achieved their goals with other companies who wish to set similar goals. Additionally, policy makers and utilities should collaborate to promote awareness of energy efficiency incentives for large customers and remove regulatory barriers, such as opt outs, to allow expansion of cost-effective utility energy efficiency programs.

The full Alliance report, key findings, and case studies are available here.